Minimizing Plastic Waste With Sustainable Packaging Solutions

Millions of tons of plastic waste are generated worldwide each year, with 79% escaping recycling processes and ending up in landfills, oceans, and natural habitats.

Plastic waste remains in the environment for centuries, some breaking down into microplastics and releasing toxic substances into the environment.

A groundbreaking solution developed by Change Plastic for Good® is tackling this problem head-on.

BDP® Biotechnology has the potential to reduce plastic waste significantly through accelerated decomposition.

This innovation has far-reaching implications for sustainable packaging. Imagine a world where plastic packaging becomes synonymous with sustainability.

This article provides the basics about BDP® Biotechnology and its role in sustainable packaging.

What Is BDP® Biotechnology?

BDP® Biotechnology is a proprietary organic ingredient that is added to plastic during the manufacturing process. It is designed to accelerate the natural decomposition of plastic and other synthetic materials like rubber, foam and yarn.

It enables products made with these materials to decompose in landfill, soil and oceans within a few years instead of centuries.

This process reduces the lifespan of plastic waste in nature, offering your business a more sustainable alternative to traditional plastic packaging.

How Does BDP® Biotechnology Work?

BDP® Biotechnology utilizes a natural process called ‘anaerobic digestion.’ These oxygen free, biologically rich environments naturally occur in landfills, swamps, the ocean floor and some compost environments.

When BDP® plastic packaging reaches these environments, it attracts microbes that thrive in these anaerobic conditions.

These microbes find the BDP® treated plastics irresistible. They consume and digest the plastic to produce vital natural byproducts such as biogas and humus. The biogas can then be captured at landfill sites or anaerobic digesters and used as natural gas. Humus is fully decayed plant matter and compost is a source of humus. With BDP® we can create humus from oil based plastics.

This is the essence of Change Plastic for Good, converting problematic plastic waste into valuable natural materials. Instead of relying solely on a circular economy, we create a regenerative system with powerful waste management applications and create truly sustainable packaging.

Revolutionizing Waste Management With BDP®

According to Science Direct, plastic makes up 18% of solid waste composition by weight in landfills.

BDP® has the potential to remove one-fifth of our total solid waste from the environment.

Landfills are expensive. If one-fifth of landfill content was decomposing alongside paper and food waste, we would need less landfill construction.

When products containing BDP® are recycled, they contribute to the creation of new items made from recycled poly.

This process helps to reduce waste and supports the circular economy by continually reusing materials.

Public and industrial awareness of how BDP® works and its benefits is also crucial.

This awareness supports the development of waste management policies and infrastructure that leverage BDP®’s potential.

Minimizing Plastic Waste With Sustainable Packaging Solutions

The Role of Digesters in Accelerating Plastic Breakdown

Digesters are facilities typically used within the dairy industry or for waste water to create natural gas from decomposing organic waste. Hotels in Mexico use problematic sargassum seaweed in digesters to power their facilities.

BDP® was designed for use in digesters because they create the perfect conditions for microbes to digest the plastic very rapidly. Here’s how it works.

The Process of Anaerobic Digestion

- Collection and Sorting: Collect and sort plastic waste suitable for anaerobic digestion.

- Shredding: Shred the plastic to increase surface area for microbial action.

- Transfer: Transfer the shredded plastic into the digester.

- Microbial Digestion: Microbes consume the plastic creating biogas and humus.

- Biogas Conversion: Biogas is scrubbed and converted to natural gas

- Fertilizer and Compost Management: Solid content is removed and sold to farms as fertilizer. The nitrogen rich liquid is also used as fertilizer and the remainder is evaporated and returned to the earth.

BDP® Biotechnology in Sustainable Packaging Production

The addition of BDP® to the production line is as simple as adding a colorant. BDP® is mixed with the plastic resin during manufacturing just like a colorant. It is dosed using a gravimetric feeder, making sure it is evenly mixed.

This even distribution maintains the packaging material’s strength, durability, and appearance.

The cost increase for producing sustainable packaging with BDP® is minimal—around 15-25% depending on volume and plastic type—much lower than compostable alternatives or switching to paper.

This makes it an attractive option for packaging manufacturers aiming to produce more sustainable solutions without increasing production costs. Let’s look at some examples.

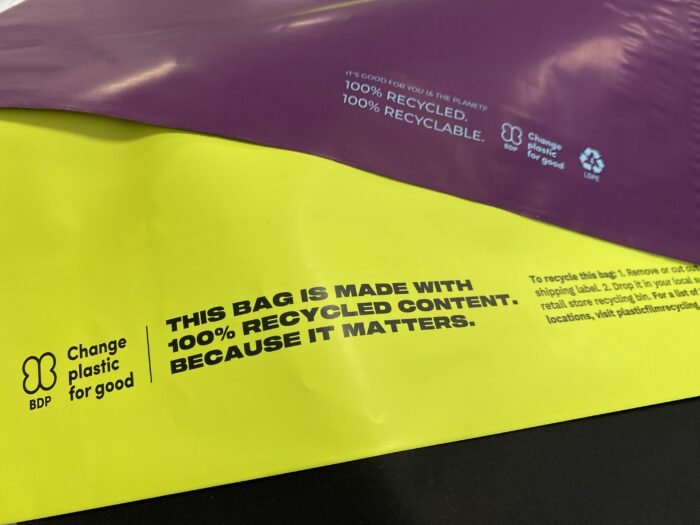

BDP® Poly Mailers

Poly mailers infused with BDP® offer a durable and lightweight mailing solution designed to decompose more efficiently after disposal.

This sustainable solution is ideal for e-commerce businesses and online retailers looking to minimize environmental impact while maximizing product protection.

BDP® Plastic Shopping Bags

BDP® plastic shopping bags offer the reliability of traditional plastic bags with the added benefit of being recyclable, reusable, and at their end of life, decompose naturally. Unlike paper which creates high levels of methane and CO2 in landfill, BDP® plastics have a 10x lower climate gas footprint than paper at its end of life.

Perfect for grocery stores, retail outlets, and markets, BDP® plastic bags provide customers with a greener solution to carry their purchases.

BDP® Plastic Catering & Restaurant Bags

BDP® plastic catering and restaurant bags blend the functionality of traditional plastic with the decomposition properties described above at a fraction of the cost of paper bags.

This reduces the environmental footprint of restaurant packaging and shifts the industry towards more sustainable practices.

Change Plastic for Good®: Leading the Way to a Sustainable Future

Change Plastic for Good® is leading the charge to bring more transparency to sustainability within the corporate landscape. Their insignia? The Butterfly.

The Butterfly logo is reserved for the most regenerative and sustainable products and packaging made with BDP®.

Similar to the famed “recycle” icon, the Butterfly is helping combat “greenwashing,” increasing consumer confidence, and reinforcing the movement toward sustainable business practices.

Whenever you buy a product, open packaging, or engage with a business certified with the Butterfly logo, you are the hero. Not only do you know your product is truly sustainable, you help clean up plastic waste from our environment, fund research for game changing advances in eco technology and become part of a truth movement with no room for greenwashing.

Moving Toward a Greener Planet With BDP® Biotechnology

The integration of BDP® stands as a powerful testament to our collective ability to push positive environmental change.

As we continue to support initiatives like Change Plastic for Good®, we invite you to join our mission to minimize waste with our sustainable packaging solutions.

Let’s move towards a more sustainable way of living and consuming.

Embrace the Future of Sustainable Packaging With CRP

Contact us today to request a quote for sustainable packaging using BDP®.