5 SIMPLE, YET IMPACTFUL PACKAGING DESIGN TECHNIQUES

When it comes to first impressions, buying decisions are often made by just that: impressions. Embossing, debossing, foil stamping, and other “pressed” finishing treatments are examples of tools designers can use to add perceived value to packaging. And what’s more – these luxury-like finishes are readily available for use on sustainable packaging.

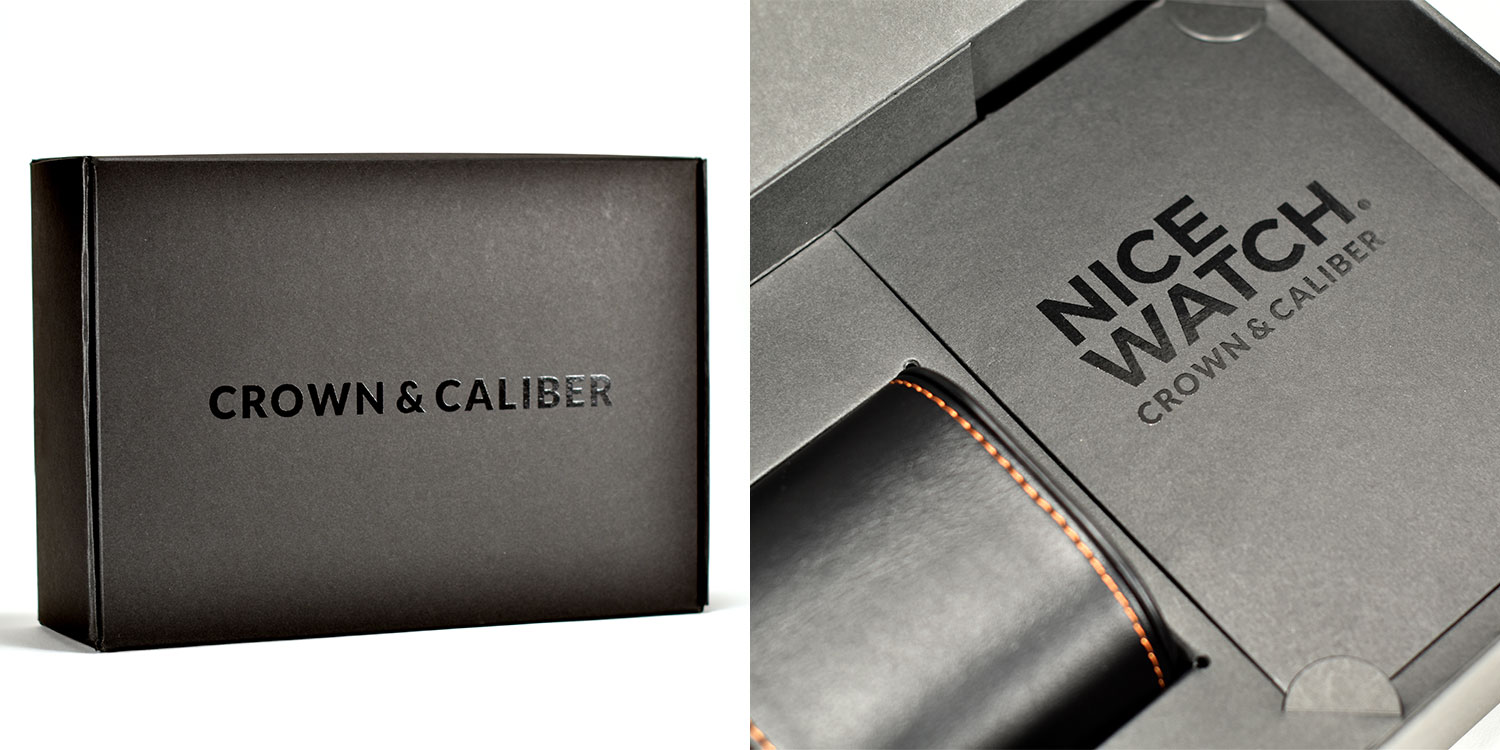

Blind Embossing or Debossing

Blind embossing and debossing are techniques that use a die to leave an impression in paper, instead of ink. This tactile form of printing can be used for text, images or patterns, playing with light and shadows on the surface of the paper.

PRO TIP: When considering this treatment, both the design and paper choice should be taken into account: in particular, bolder type and large designs can be embossed more deeply, and heavier papers can achieve greater depth and detail.

FOIL STAMP

Foil stamping is a method of applying colored or metallic foils to a surface for an elegant look. Much like embossing, foil stamping uses a combination of heat and pressure to stick foil to a printed substrate. Many luxury brands use the technique of foil stamping their packaging in gold or silver to connote a premium product. Combined with embossing or debossing, the effect can be even more impactful – literally.

PRO TIP: If budget is limited, consider the size of the area you’d like to have foil stamped (for example, small scripts and logos), or explore premium metallic inks as an alternative. They won’t match the shine of foil, but they can mimic the desired look when printed on the right surface.

CLEAR or HOLOGRAPHIC HOT STAMP

Hot stamping is a lithography printing process that uses heated image molds or stamping dies to transfer metal foils or pre-dried inks onto a surface. Clear or holographic foils are a great way of using a subtle method to highlight a design on a substrate. It achieves a simple reflection, highlighting the area to the eye. Adding this effect to dark or similar tone paper or ink colors can create a bold design.

PRO TIP: Hot stamping doesn’t work well with extremely small letters or designs, as it loses detail. Another key consideration is the choice of material for the die that presses the stamping foil. Metals like brass, copper, magnesium, and steel are commonly used. Magnesium dies are easiest and least expensive, but are less durable. Copper and brass offer greater durability and require greater costs to produce, while hardened steel dies are virtually indestructible and provide the best foil transfers. Steel dies are expensive to produce, but due to their durability, become incredibly cost-effective when used in high-volume production runs.

Overall Embossed or Debossed Pattern

Want the look of a specialty paper without buying specialty paper? Embossing patterns are one of the easiest ways to achieve a unique look and feel. Options can range from leather to fabric, wood grain or other decorative patterns, and are achieved via the use of a large embossing cylinder, pressed into paper or board.

PRO TIP: Many factories keep patterned embossing dies on-hand and have a great selection to choose from, so if you’re tight on budget, be sure to ask what options may be readily available. If you want to go even more luxe, custom dies can be made with your specific pattern.

Spot UV

Spot UV refers to the application of a clear coating to a specific area (or areas) of a printed piece, which is then cured by UV light. This is a creative and economical way to add depth and contrast through varying levels of sheen and texture. It can be applied in thicker layers to create an embossed or raised effect, either in small areas or in pattern-like applications.

PRO TIP: Spot UV can be used as a design element on paper without the use of ink. If used on its own, it offers the best contrast when applied over a darker substrate.

SUSTAINABILITY NOTES

Embossing & Debossing: This technique is only as sustainable as the substrate you choose. Opt out of coated board or paper to ensure recyclability, and consider using recycled materials when possible.

Foil & Hot Stamps: A study from the Foil Stamping & Embossing Association (FSEA) tested foil-decorated paper and board and found that both hot and cold foil stamping processes were recyclable and re-pulpable. This is a great advantage if you’re marketing to environmentally-conscious buyers.

Spot UV: The print industry reports that packaging with Spot UV treatment is included in the “mixed waste” category of recycled stock, so long as the substrate you choose is recyclable. According to this report, UV coatings also have the following benefits:

They don’t release VOCs into the atmosphere, as solvent-based coatings do.

Because they don’t require the application of heat for the drying process and are cured through the application of UV light, less energy is used in their application.

They are less flammable than solvent-based materials