Table of Contents

HOW TO WRITE AN EFFECTIVE PACKAGING RFQ

The current market is volatile to say the least.

Tariffs shift. Lead times stretch. Costs swing without warning.

This is the world we’re living in.

And it’s not going away anytime soon.

The supplier you counted on for packaging is now a question mark.

To make matters worse, every brand that needs packaging is converging on the top companies in low-tariff zones as we speak.

You have to act fast.

Cue the search process.

You reach out to known suppliers and ask for referrals.

You Google packaging companies, packaging suppliers, or packaging procurement, and scroll through endless results.

You fill out form after form, repeating the same specs again and again.

This is where a solid packaging RFQ can make all the difference.

In this post, we’ll explain the basics of packaging RFQs and show you how to write one that saves time and simplifies your search.

What is an RFQ?

An RFQ, or Request for Quote, is a purchasing tool used to request pricing from packaging procurement.

It is used when you already know the exact specifications of the packaging you need.

An RFQ helps you collect comparable quotes for items such as shopping bags, e-commerce mailers, to-go bags, or custom packaging materials.

It differs from a Request for Proposal (RFP), which asks vendors to suggest creative ideas or solutions.

The goal of an RFQ for packaging procurement is to evaluate suppliers based on price, quality, service, and delivery timeline.

Why Write an RFQ?

Nobody knows when the packaging industry will settle.

You may have to switch packaging companies often or build a vast network of suppliers.

Writing a Request for Quote (RFQ) helps your brand:

- Get accurate pricing from multiple packaging suppliers.

- Compare vendors on cost, quality, and delivery.

- Ensure consistency with clear requirements.

- Save time and money in the selection process.

- Reduce risk by choosing reliable partners.

The RFQ Process for Packaging Procurement

Since the whole point of an RFQ is to standardize and organize your decision-making process, it’s best to define what you’re looking for from the beginning.

Follow these steps to create the best RFQ for packaging procurement.

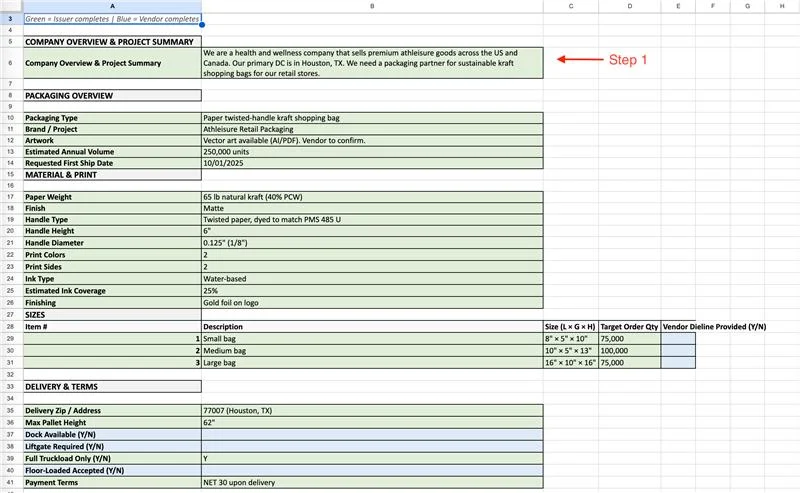

Step 1: Company Overview & Project Summary

It always helps to give vendors some context for the project they will be bidding on.

This can include a brief introduction to your company and a general overview of your packaging program’s requirements.

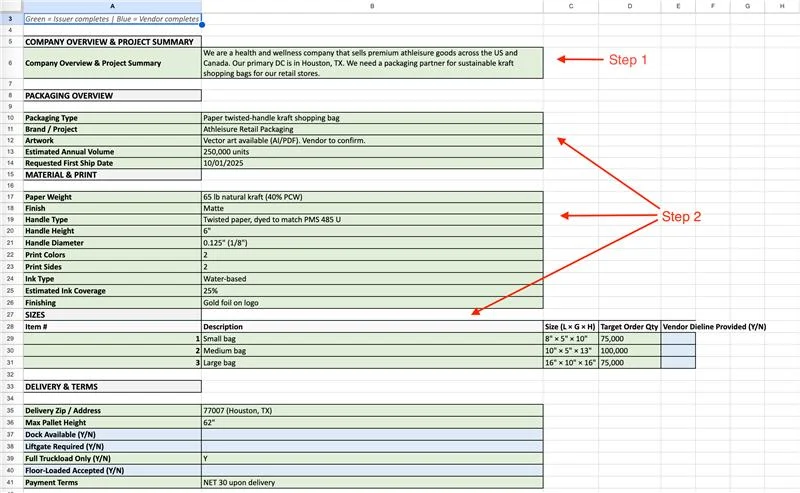

Step 2: Fill In the Packaging Overview

Packaging Type

Is it a shopping bag, mailer, or takeout bag? Be as specific as possible.

Size(s)

Include all dimensions with the unit of measurement. If you have dielines or a CAD mock-up, that always helps to clarify.

PRO TIP: Use this standard of measurement for most bags with side and bottom gussets: Length x Gusset x Height. If specifying a bag with just a bottom gusset (and no side gusset), clearly label it BG. For example: 10” x 4” (BG) x 14”.

Material

Be sure to specify the type of material, the weight/thickness, and the percentage of recycled material content.

Handle Specs (for bags)

Do you have a handle material specified?

If so, include these specs:

- The type of handle

- Height (from the middle of the handle to top of bag)

- Diameter

- Color

- Attachment style

Print Specs

If you don’t already have artwork available, you should at least provide these specs:

- Number of print colors

- Estimated percentage of ink coverage

- Type of ink

If art is available, include this with your RFQ, and the vendor can help with specifications.

Finishing

This should be where you add any special features that would need to be considered, such as:

- Embossing

- Debossing

- Foils

- Hot stamping

- Turn tops

- Glue strips

- Perforations

The more specific you are, the better.

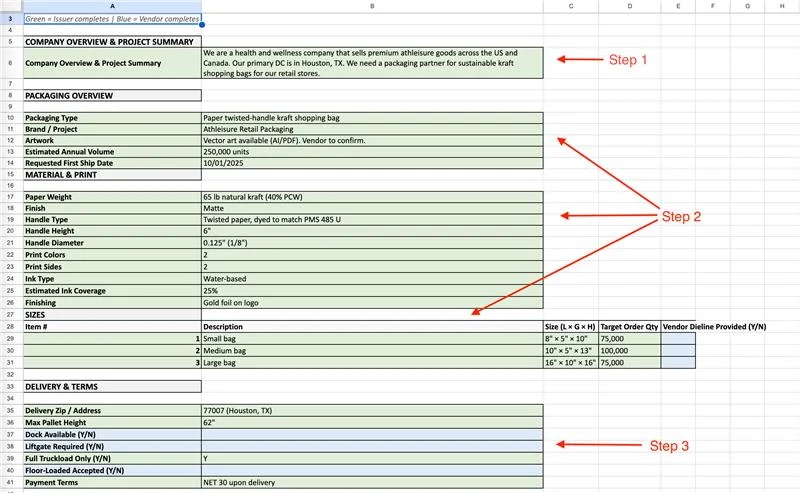

Step 3: Describe Your Delivery & Terms

If you have a specific way you’d like your finished product case packed, be sure to include that in your RFQ.

This could mean specifying the type of inner packing, the case pack quantity, or container assortment you’re looking for.

Delivery Location(s) & Instructions

Do you have a warehouse with a loading dock, or will your deliveries require liftgate delivery?

Max Pallet Height

Do you have a max pallet height?

Does your order need to be palletized, or can it be delivered in floor-loaded containers?

The more details you can provide, the better it helps with logistics.

This will allow you to determine your actual delivered pricing to compare across vendors.

PRO TIP: If logistics isn’t a factor for you, you can specify this by asking vendors to quote “FOB Mill.”

Payment Terms

Specifying your desired payment terms is essential, as it will ensure your bidders are being compared apples to apples.

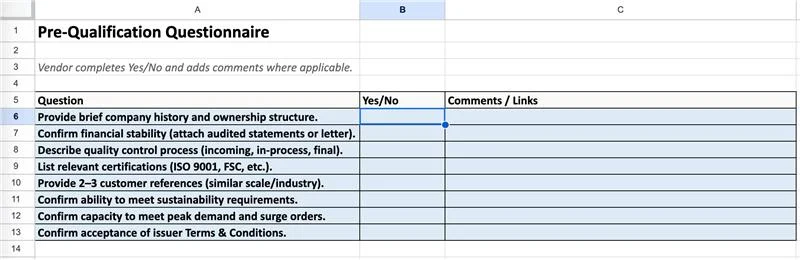

Step 4: Create a Pre-Qualification Questionnaire

Vendors often are vetted during the request for information (RFI) process.

But if you wait until the RFQ to make sure you are working with qualified packaging companies, include a questionnaire in your RFQ.

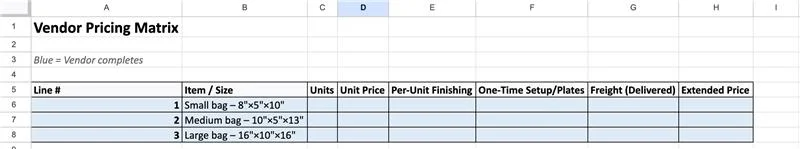

Step 5: Set up a Pricing Matrix

A pricing matrix lets you compare bids easily.

This can be done in any spreadsheet or any other table-like format that works best for you.

The goal is to have all the information for a specific product in the same format so you can compare the quotes easily.

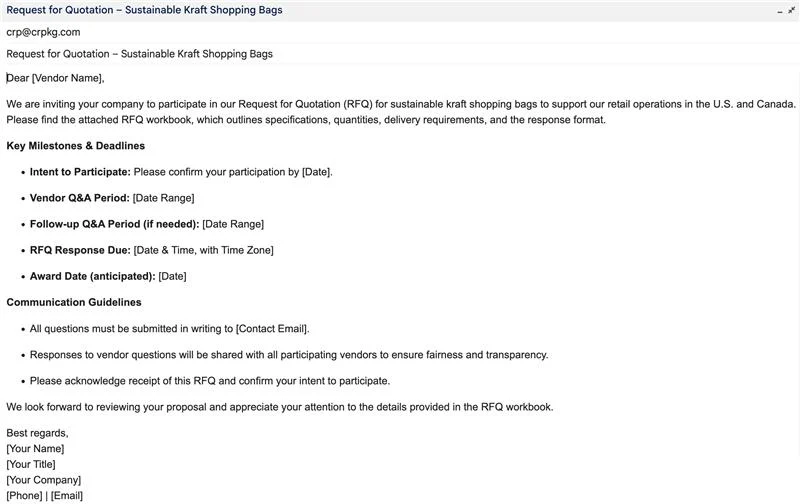

Step 6: Set Expectations & Manage Communication

Specify your timeline for important milestones such as:

- Intent to Participate

- Vendor Q&A Period

- Follow-up Q&A Period

- Cut-off time for RFQ responses

- Award Date

Be sure to include all vendors in responses to questions.

The more transparent you are with everyone, the better your RFQ results will be.

Keep track of your responses and acknowledge them as you receive them.

Step 7: Review Bids and Award the Contract

Once all submissions have been received within the timeline you established, it’s time to review quotes.

If you use this guide to organize your RFQ, it should be relatively easy to compare bids.

It’s up to you to make your selection, based on price and any other factors that may be important to you, such as:

- Production timeline

- Quality control policies

- Reference checks

- Sustainable best practices

Step 8: Close the Loop

Once you have selected a new packaging company, you may finalize the contract by making sure all details are accounted for in a purchase order or another formal document.

If your RFQ was detailed enough, all should be outlined as specified, but make sure to double- or triple-check for accuracy.

Once the agreement is finalized, it is customary to let the other vendors know they were not selected.

If you’d like, you can include reasons why to allow them the chance to grow or be considered during your next RFQ.

That decision is up to you.

Make the Switch to Packaging That Works for You

Switching packaging suppliers can feel overwhelming, but the right partner makes the process seamless.

At Creative Retail Packaging, we turn complex challenges into time-saving solutions.

Our team combines decades of industry expertise with a commitment to sustainability and innovation.

Should demand change or tariffs shift, our global network gives you flexibility in procurement.

Source smarter with our strategic solutions.